Case Study | Title: Purchase Order (PO) Ageing

Case Study | Title: Purchase Order (PO) Ageing

By Simran Mahajan

PGDRM Batch Jan’20-21

What is a PO?

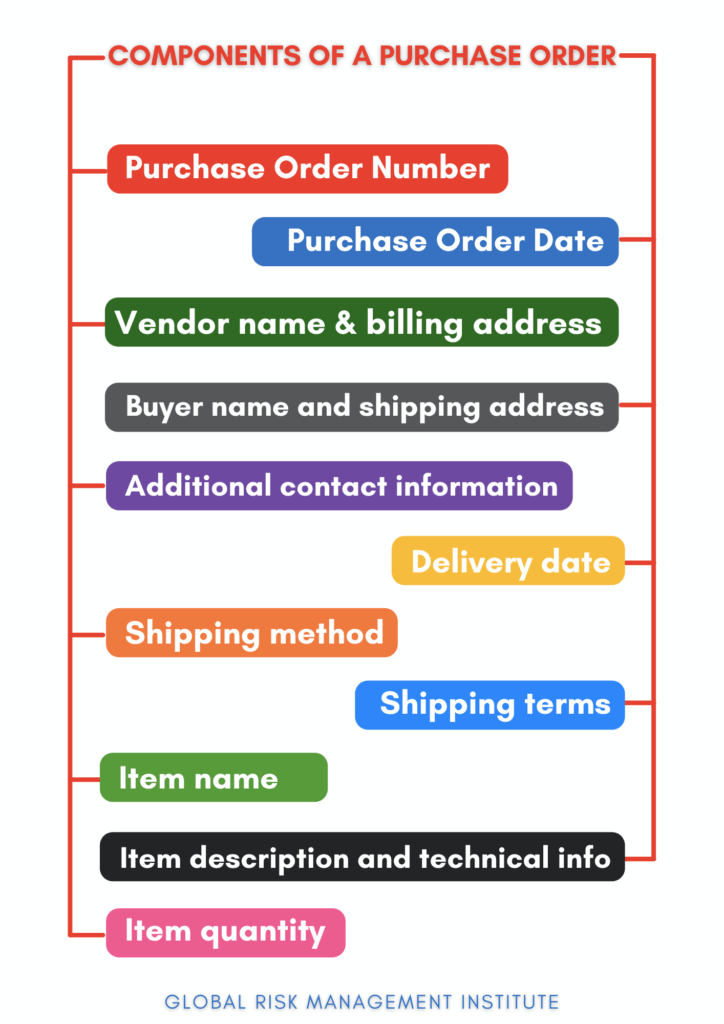

- A Purchase Order (PO) is a document sent from a buyer to a supplier with a request for an order.

- Purchase orders help you account for all the goods and services your company has ordered.

- They allow you to track orders more confidently, knowing that your supplier is contractually bound to deliver them at a specific time and date.

- A PO is issued once the Purchase Requisition (PR) has been made.

What is an Open PO?

An Open PO, also called a standing PO, means the supplier has not fulfilled the agreed purchase order.

It can also mean the supplier has fulfilled it, but the company has rejected the goods due to quality issues and requested a re-supply.

Closed PO – As per the agreed PO, the material has been received from the vendor, and the PO has been fulfilled.

What is PO Ageing?

Purpose – To identify open and delayed POs that have not yet been fulfilled.

Monitoring Open POs – We check whether the goods have been received or not.

We also ensure that any open POs are not closed with unauthorized material/service receipts or invoices.

PO Ageing Reports/Data

- Formation of PO Ageing Buckets – This is done to keep track of purchase orders so that vendors can be followed up accordingly. The aging buckets are usually divided into time periods such as 0–15, 15–30, and 30–60 days.

- PO Ageing Report – This report contains the bucketing period and lists the open POs in each category. It also includes the vendor details for reference.

Analytics We Can Perform

- Production Delays – Delays in customer orders can lead to emergency purchases at a higher cost. In some cases, the order may not be fulfilled at all. The root cause should be identified to understand why such POs were raised. This can include checking vendor contracts and vendor history.

- Empty Shelves and Revenue Loss (Retail) – Stock shortages can directly result in empty shelves and loss of revenue.

- Uncanceled POs and Vendor Risks – Material may be purchased from other vendors without canceling the original PO. In such cases, the original vendor could deliver or dump the material at a later date.

- Multiple Open POs for the Same Item – This can lead to excessive inventory, causing storage and cost issues.

- Procurement at Higher Costs – Materials may be purchased from the same or other vendors at a higher cost, even while lower-cost POs remain open.

- High-Cost POs in Volatile Markets – High-cost POs may be used to pay extra to vendors, especially in products like cocoa or copper, where price fluctuations are common.

- Delays in Maintenance Spare Procurement – Delays in obtaining maintenance spares can lead to plant stoppages.

- Material Requirements and Open POs – It is important to check if the required material is still needed when a PO remains open. Link this back to PRs and review budget leftovers or month-end requirements.

Disclaimer

This report has been produced by students of the Global Risk Management Institute (GRMI) for research, classroom discussions, & general informational purposes only. While care has been taken in gathering the data and preparing the report, neither the students nor GRMI make any representations or warranties as to its accuracy or completeness. All warranties that might otherwise be implied are expressly excluded to the maximum extent permitted by law. References to collected information have been provided where necessary.

GRMI and its students accept no responsibility or liability for any loss or damage of any nature suffered by any person as a result of acting, or refraining from acting, in reliance on any statement, fact, figure, opinion, or belief contained in this report. This report does not constitute any form of advice.

You may also like

Courses After BCom With Highest ROI

FRM Full Form and Its Importance in Finance